Hits: 144 img

Aerogel glass replaces Low-E glass

Aerogel materials can also be used to make energy-saving glass, which is a certain substitute for traditional Low-E coated glass. Through two pieces of glass, aerogel is sandwiched in the middle to form a "sandwich" structure, which has good thermal insulation, sound insulation, fire resistance and other properties. Aerogel energy-saving glass can be used in buildings with high energy-saving requirements. At the same time, it can replace the general curtain wall glass of high-rise buildings, greatly reduce the weight of the building, and play a fire-proof role. Compared with other types of glass, aerogel glass can help buildings better achieve energy saving, comfort and environment.

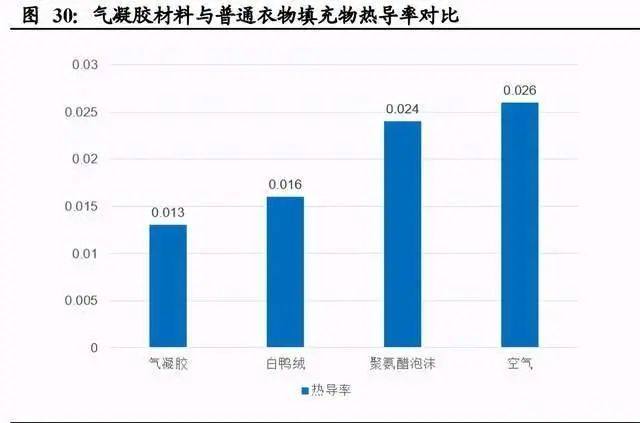

Aerogel materials have great advantages in making outdoor protective equipment, and can be processed into lighter and thinner clothing with equally excellent thermal insulation performance. The thermal conductivity of aerogel materials is lower than that of white duck down, the filling material of down jackets on the market, and is half the thermal conductivity of air. When aerogel is made into ready-made clothes, the thickness of aerogel ready-made clothes is 1/4 of that of traditional warm clothing under the same warming effect.

Improvement in aerogel cost is beneficial to domestic development

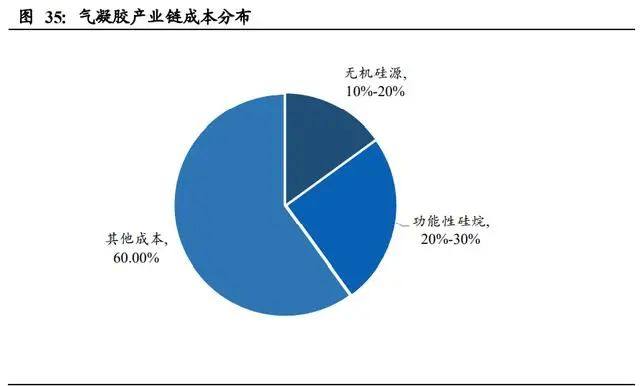

Compared with traditional insulation materials, aerogel has obvious advantages, but its disadvantages are still prominent: high production costs and expensive products. The production cost of aerogel is mainly concentrated in the raw material silicon source, equipment depreciation and energy consumption. Among them, equipment depreciation and energy consumption costs account for about 60% of the total cost of the industrial chain. Effective cost reduction depends on breakthroughs in preparation technology on the one hand, and on the large-scale industrialization of low-cost raw materials on the other.