Aerogel is mainly used in wall insulation materials, thermal insulation coatings and energy-saving glass in the field of building materials, targeting two major scenarios: new buildings and energy-saving renovation of existing buildings. my country's increasingly improved building energy consumption standards and the gradually established building energy-saving operation supervision system will promote the rapid development of the building wall insulation materials industry; in recent years, the real estate market has moved towards high quality, and the growth rate of development investment has remained at around 10% year after year, which will drive the rapid development of the insulation building materials market. We make a mid-term estimate of the market space. In the next ten years, the potential market size of aerogel used in building materials in my country is about US$2.9 billion, of which wall insulation materials are the main part, about US$2 billion.

1. The penetration rate of internal and external walls will increase significantly

According to the different use locations, the wall insulation materials of buildings can generally be divided into external wall insulation materials and internal wall insulation materials. The application of aerogel can greatly improve the insulation and flame retardant properties of the wall and reduce environmental impact.

It is estimated that by 2030, the domestic market size of aerogel materials for exterior wall insulation will be US$1.1 billion; the domestic market size of aerogel materials for interior wall insulation will be US$900 million, totaling US$2 billion.

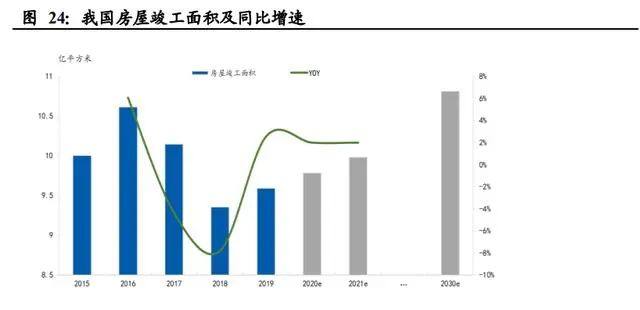

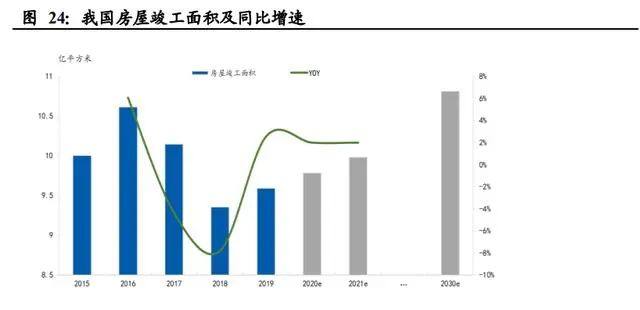

Aerogel exterior wall insulation materials are suitable for high-end buildings with lightweight and green requirements and special buildings with strict insulation requirements. The application prospects are optimistic, and the estimated potential market size will reach US$1.1 billion. Exterior wall insulation materials are divided into four grades according to the degree of flammability: A, B1, B2 and B3. Currently, B1 and B2 grade products are commonly used in construction, mainly polystyrene boards, polyurethanes, etc. Polystyrene boards are cheap and widely used, but they are easily deformed by heat; polyurethane has more ideal performance and is the mainstream exterior wall insulation material in Europe and the United States, but its penetration rate in the Chinese market is less than 10%. my country currently has the world's largest construction market, with a completed housing area of 960 million square meters in 2019. The area of exterior walls is generally calculated as 0.7 times the building area. In 2019, the newly added exterior wall area was 672 million square meters. Assuming that the compound growth rate of the completed housing area in my country in the next ten years is 3% according to the neutral assumption in the market, aerogel materials can seize part of the high-end market, referring to the current 10% penetration rate of polyurethane materials in China's building insulation market. Then by 2030, the newly added exterior wall area will reach 930 million square meters. Assuming that it is calculated according to the penetration rate of 10%, the application volume of aerogel materials in exterior walls will reach 93.02 million square meters. Existing technical patents show that most aerogel materials are applied to wall materials in the form of single-layer felt. According to the calculation of 80 yuan/square meter for 10mm aerogel felt, the potential market size of aerogel exterior wall insulation materials can reach 1.1 billion US dollars.

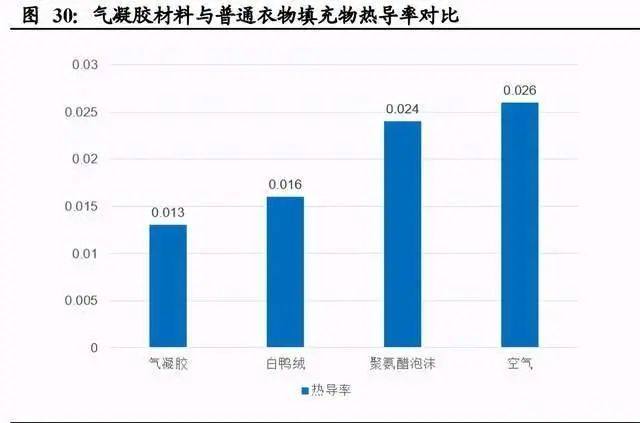

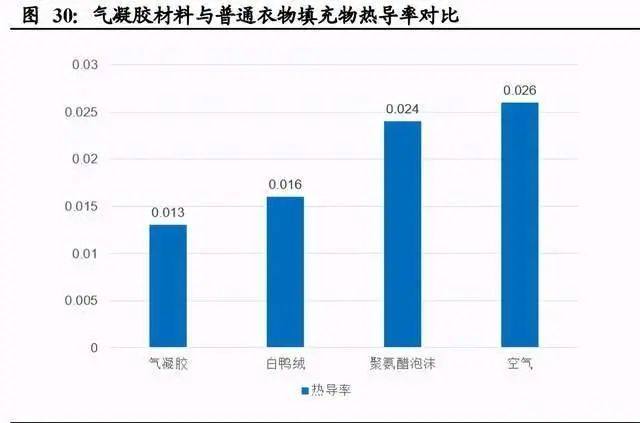

Aerogel has become an ideal interior wall insulation material due to its advantages of strong heat resistance, light weight, non-toxicity and easy degradation, with an estimated potential market size of US$900 million. Due to differences in climate and living habits, the preferences for interior wall insulation materials in the south and north of my country are significantly different. Interior wall insulation materials are more popular in the north. Currently, the commonly used interior wall insulation materials are mainly polyurethane foam materials and insulation boards, of which the latter is the main one. In 2019, the completed housing area was 960 million square meters. The interior wall area is usually calculated as 2.7 times the building area. In 2019, the newly added interior wall area was 2.592 billion square meters. The demand for interior wall insulation materials mainly exists in the areas north of the Yangtze River in my country, and the area with demand for interior wall insulation materials accounts for about 55% of the newly added interior wall area in the country. According to the requirements of the "Action Plan for the Promotion and Application of New Wall Materials", the application ratio of new insulation wall materials in new buildings needs to reach 90%, and the newly added insulation interior wall area is about 1.283 billion square meters. Assuming that the compound growth rate of the completed housing area in my country is 3% in the next ten years, and assuming that the penetration rate of aerogel interior wall applications reaches 2%, by 2030, the newly added interior wall area in my country will be 3.588 billion square meters, and the demand for aerogel interior wall insulation materials will be about 71.76 million square meters. According to the calculation of 80 yuan/square meter for 10mm aerogel felt, the potential market size of aerogel interior wall insulation materials can reach US$900 million.

2. New market for architectural coatings is expected to open up

Insulation coatings are a branch of the coatings market, and aerogel materials will participate in the competition in the future coatings market. In 2019, the global coatings market size was about 919.5 billion yuan, of which architectural coatings accounted for 39%, and the Chinese coatings market was 300 billion yuan, of which architectural coatings accounted for 29%.

Generally speaking, coatings can be divided into organic coatings and inorganic coatings according to their chemical properties. Among them, organic coatings can be divided into three categories according to their uses: architectural coatings, OEM coatings (Original Equipment Manufacture, equivalent to the commonly used industrial coatings in China) and special coatings.

Aerogel coatings have the advantages of fire retardancy, sound insulation and noise reduction, reducing the difficulty of inorganic waste treatment in buildings, and simplifying construction procedures. They will be widely used in the coating market in the future. Aerogel coatings are water-based coatings with functions such as thermal insulation, sound insulation and noise reduction, earthquake resistance, and fire prevention, which are prepared by dispersing aerogel powder in a special high-performance resin emulsion or compounding with an inorganic binder system using a special process. Water-based aerogel coatings use SiO aerogel as the main functional filler, water as the solvent, inorganic system, safety and environmental protection, and have a high degree of attention.

The potential market size of aerogel coatings for building insulation in China is US$900 million. From the perspective of market demand, thermal insulation properties can make ordinary building coatings popular. In 2019, China's production of building coatings was 6.94 million tons, a year-on-year increase of 7%. In 2019, the per capita output of architectural coatings in my country was only 5.0 kg/person, significantly lower than the 7.9 kg/person in the United States. With the continuous release of future stock demand, the increase in per capita output will drive the continuous growth of architectural coatings production. At the same time, aerogel coatings that are lightweight, environmentally friendly and have thermal insulation properties will also be favored by more consumers. Assuming that the per capita output of architectural coatings in my country reaches 7.9 kg/person within ten years, the output of architectural coatings in my country will be 11.06 million tons in 2030. At the same time, considering the customer's preference for functional architectural coatings, we assume that the market penetration rate of aerogel environmentally friendly thermal insulation coatings will be 10% in the next ten years. According to the mass components of aerogels in several current aerogel coating patent methods, assuming that the mass of aerogels added to the coating accounts for 12%, my country has an annual demand for 53,000 tons of aerogel coatings. According to the current market price of SiO2 aerogel coatings of 45 yuan/kg, the potential market in this application field is about US$900 million.

3. Aerogel glass replaces Low-E glass

Aerogel materials can also be used to make energy-saving glass, which is a certain substitute for traditional Low-E coated glass. Through two pieces of glass, aerogel is sandwiched in the middle to form a "sandwich" structure, which has good thermal insulation, sound insulation, fireproof and other properties. Aerogel energy-saving glass can be used in buildings with high energy-saving requirements, and can also replace general curtain wall glass in high-rise buildings, greatly reducing the weight of the building and playing a role in fire prevention. Compared with other types of glass, aerogel glass can help buildings better achieve a balance between energy saving, comfort and environment.