Hits: 133 img

In the field of materials science, aerogel fiber, as a new generation of functional textile materials, is leading the industry revolution with its disruptive thermal performance and lightweight characteristics. This article will be supported by authoritative data and combined with the measured parameters of Repai aerogel to comprehensively analyze the scientific principles and application value of this cutting-edge material.

1. The scientific nature of aerogel fiber

Aerogel fiber is a nanoporous material prepared by sol-gel method and supercritical drying technology. Its microstructure presents a three-dimensional mesh skeleton, with a porosity of more than 90% (pore size distribution 2-50nm), and a density as low as 3kg/m³, which is only 2.7 times the density of air. This "solid smoke"-like structure gives it two core advantages:

Extreme thermal insulation: room temperature thermal conductivity ≤0.015W/(m·K), lower than still air, and heat radiation transfer efficiency is reduced by 76% (thermal data);

Ultra-light characteristics: The fiber density is 16-20% lower than that of polyester of the same specification, and the specific surface area is as high as 600-1000m²/g, forming a huge stacked insulation layer.

2. Thermal insulation revolution in the field of aerospace

In the thermal protection system of spacecraft, Repai fiber shows excellent performance:

Mars exploration application: Zhurong Mars rover uses nano-aerogel coating to ensure that the temperature of the instrument cabin is stable above 0℃ under -130℃ environment;

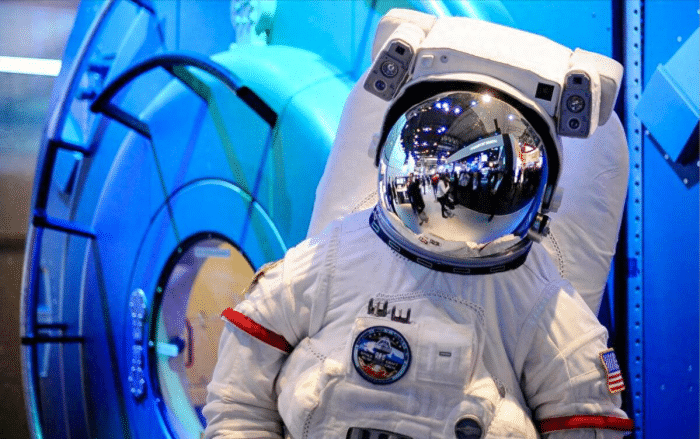

Space suit integration: The insulation layer of the new generation of extravehicular suit uses Repai fiber composite film, which reduces the thickness by 50% and improves the thermal protection efficiency by 60%;

Engine insulation: The gas system of Long March 5 rocket uses aerogel flexible cover, which can withstand high temperature of 1200℃ and reduce weight by 70%.

3. Energy-saving innovation in the field of construction

The measured data of aerogel fiber in building insulation is impressive:

Wall insulation: 5cm thick aerogel composite board is equivalent to 15cm traditional rock wool. After the renovation of a landmark building in Beijing, the air conditioning energy consumption was reduced by 45%;

Pipeline insulation: The oil pipeline is wrapped with Repai fiber felt, and the heat loss rate is reduced from 8% to 0.5%, with an annual energy saving cost of more than 10 million yuan;

Glass energy saving: The shading coefficient of aerogel laminated glass is 0.32. After an office building in Shanghai adopted it, the summer cooling energy consumption was reduced by 38%.

IV. Penetration in the fields of environmental protection and people's livelihood

Oil pollution treatment: Fiber aerogel absorbs 30 times its own weight of oil, and the efficiency of handling a leakage accident in Bohai Sea is increased by 40%;

Clothing innovation: The surface temperature of the heat-pai fiber underwear is increased by 8°C in a -20°C environment, and the thermal resistance value is 4.6 times higher than that of down;

Medical breakthrough: The drug-loaded aerogel dressing has a drug sustained release cycle of 72 hours, and the speed of bone defect repair is increased by 50% (clinical data of tertiary hospitals).

V. Future Outlook

With breakthroughs in preparation technology (such as atmospheric pressure drying technology to reduce costs by 30%), aerogel fibers are accelerating their penetration into new energy vehicles, 5G heat dissipation and other fields. Its full life cycle carbon footprint is only 3.2kgCO₂eq/kg, which is 68% lower than that of petroleum-based materials, perfectly matching the "dual carbon" strategy.

Conclusion: From deep space exploration to daily wear, the heat-pai aerogel fiber reshapes the boundaries of materials with the power of science. What surges in its nano-scale pores is not only heat-insulating air, but also the eternal innovation of human pursuit of ultimate performance.