Aerogel material itself has the disadvantages of low strength and high brittleness, in order to overcome this shortcoming, it is necessary to modify the aerogel material, which is the most important process at present, through modification can give the aerogel material different properties. At present, the most commonly used method to modify aerogel materials is doping, that is, adding dopants or strengthening/toughening materials to prepare composite aerogel materials.

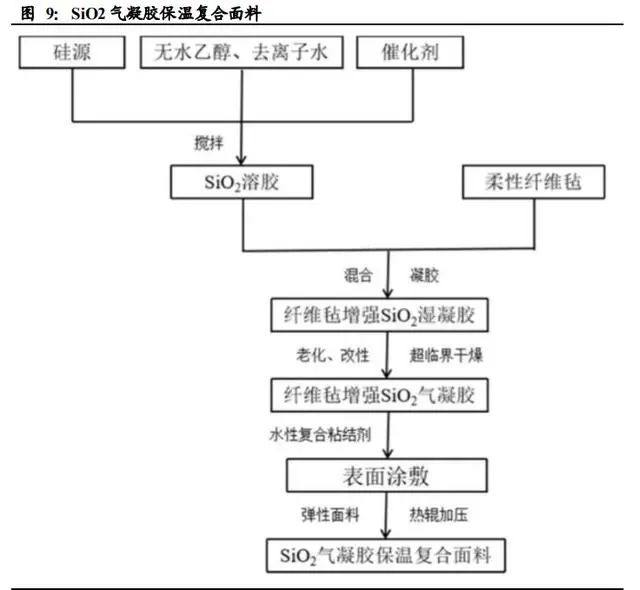

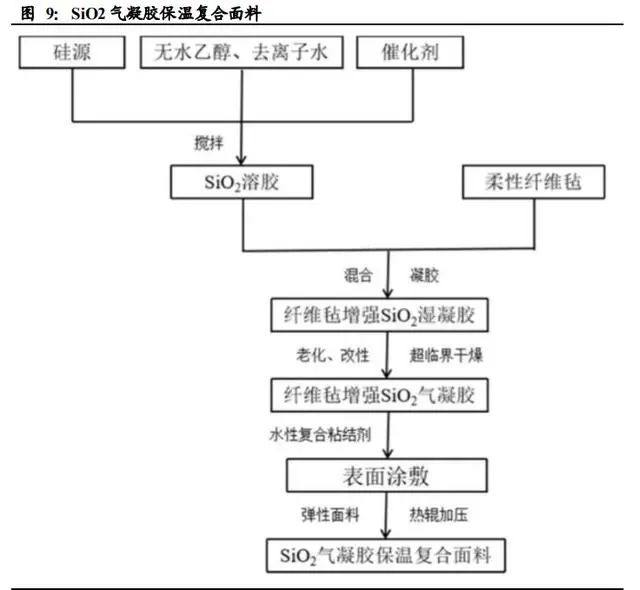

There are usually two methods to prepare composite aerogel materials: one is to add doping materials before the gel process; The other is to prepare aerogel particles or powders, then add doping materials and binder, and then make a secondary formed complex by molding or injection molding. Commonly used doping materials are glass fiber, mullite fiber, rock wool, aluminum silicate fiber and so on. The choice of doping materials mainly depends on the application purpose of aerogel composites.

Aerogel can be combined with glass fiber, ceramic fiber or carbon fiber to improve the binding force of the system, so that the surface is not easy to crack and powder. Common products such as aerogel glass fiber felt, aerogel ceramic fiber felt, pre-oxygenated fiber, etc., such products are mainly used in pipeline furnace body and other thermal insulation, can replace polyurethane foam, asbestos insulation pad, silicate fiber and other non-environmental protection, poor insulation performance of traditional flexible thermal insulation materials.

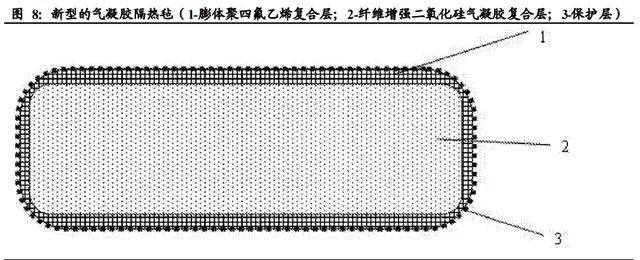

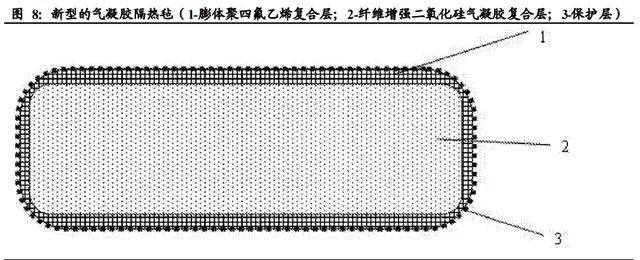

The composite of aerogel matrix material surface with higher strength and toughness can improve the strength of the whole material system and expand more application fields. Although the pure fiber felt has the effect of heat insulation, the surface fiber is easy to break and powder, causing floating fiber or powder pollution, which is not suitable for long-term use under high temperature, compression and vibration conditions. In order to solve this problem, a new aerogel material composite method has appeared in the market. The aerogel composite layer is covered with a layer of higher strength, high toughness materials such as expanded polytetrafluoroethylene and flame retardant PET fiber composite layer, which can be used in special fields such as automotive insulation.

Aerogel materials can also be used as coating materials to add thermal insulation protection to the surface of the substrate. Aerogel adhesive composition is prepared by mixing aerogel particles with adhesive, flame retardant and blowing agent, and then coating the surface of aerogel coating with heat reflection layer, the heat resistance of the raw material can be greatly improved.

Aerogel materials can also be used in conjunction with flame retardants to obtain better flame retardancy while also improving the strength and toughness of the material. There is a Sb2O3-SiO2 composite aerogel inorganic flame retardant, with a large specific surface area, it and plastic, rubber and other polymer matrix to produce a strong interface adhesion, improve the dispersion of composite aerogel flame retardant in the polymer melt, fluidity, improve the flame retardant effect. The loss of mechanical properties of polymer matrix caused by adding inorganic flame retardants is reduced.

Aerogel materials can also be made into clothing fabrics with textile fibers such as non-woven fabrics, polyester staple fibers, nylon, etc., which can be used in down jackets, cotton-padded jackets, outdoor supplies, fire-resistant clothing, space suits and special work clothes. The material has good thermal insulation, heat insulation, wear resistance, water resistance, wind proof type, thermal conductivity is lower than 0.05W/(m "K), lower than the thermal conductivity of down wool.