Hits: 156 img

With the increase in new energy electric vehicles, the safety of lithium batteries, the core component, cannot be ignored. According to data from the Fire and Rescue Bureau of the Ministry of Emergency Management, a total of 640 new energy vehicle fires were reported in China in the first quarter of 2022. Compared with the same period last year, it increased by 32%, higher than the average increase of 8.8% in vehicle fires. The biggest cause of these fires is battery thermal runaway.

Generally, the operating temperature of lithium batteries is -20℃~45℃. There are also some wide-temperature batteries with operating temperatures of -40℃~60℃, or even lower or higher. However, in actual use, there are many reasons that may cause thermal runaway of lithium batteries, which in turn cause fires.

When the lithium battery is at high temperature for a long time, the chemical reaction activity of the lithium battery is enhanced, the side reactions are also enhanced, and the aging process is aggravated, which can easily lead to problems such as dissolution of positive and negative electrode materials; when it is at low temperature for a long time without adjustment, it is very easy to have lithium precipitation problems at the negative electrode, and then lithium single substance accumulation is formed, causing internal short circuit and thermal runaway. Therefore, it is very necessary to take thermal management protection measures for lithium batteries. Safety is usually ensured from two aspects. One is to optimize the layout and curb the probability of thermal runaway causes, which tests the comprehensive capabilities of the company; the other is to find protective materials to limit the time and area of accident spread during thermal runaway, which is also the mainstream choice.

The "Safety Requirements for Power Batteries for Electric Vehicles" officially implemented on January 1, 2021 takes the safety of lithium battery systems as the focus of assessment, and adds a new system thermal diffusion test, requiring that after the battery cell has thermal runaway, the battery system will not catch fire or explode within 5 minutes, and puts forward new requirements for the fire prevention and heat insulation performance of the battery module during thermal runaway. Prior to this, the launch of the "Aerogel Insulation Sheet for Lithium-ion Power Batteries" standard, which was compiled by lithium battery companies such as BYD and Yiwei Lithium Energy in June 2020, indicated that aerogel materials can be used as the development direction of thermal management materials for new energy vehicle batteries, breaking the game!

[Solution]

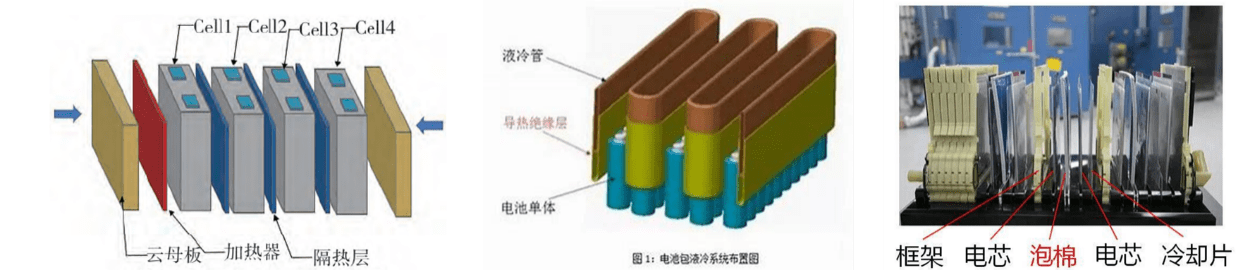

With the development trend of high volume energy density of new energy vehicle batteries, aerogel has outstanding advantages as a thermal insulation material used in thermal insulation of narrow spaces of battery cells. This innovation center forms a comprehensive protection solution around aerogel + lithium battery. First, fireproof aerogel thermal insulation materials are placed between each battery cell (square, cylindrical or soft pack), supplemented by thermal conductive materials, which can not only assist thermal management in advance, but also slow down the spread of fire in case of thermal runaway, truly realizing the functions of "insulating heat when cold, dissipating heat when hot, and blocking fire when on fire", and protecting new energy.

1. Aerogel flame retardant sheet

By coating aerogel sheets, not only can the problem of plastic sealing not being flame retardant be solved, but also the problem of powder loss can be solved. In an environment below 600°C, the thermal conductivity of aerogel increases slowly with temperature, but above this temperature, the thermal conductivity increases rapidly. Therefore, this innovation center has also developed a high-temperature, low-thermal conductivity, high-radiation coating that forms a sandwich structure with aerogel sheets, so that it still has efficient thermal insulation performance in the event of thermal runaway, delaying the spread of heat.

2. Efficient directional heat conduction

Combining aerogel flame retardant sheets with heat dissipation materials to form a directional heat conduction and heat dissipation system, the internal temperature is quickly released. By building a simulation test bench, that is, under the irradiation of the heat source, the sample is placed at a distance, and the heat insulation and heat dissipation material is covered on the heat source side. The other side is tested with an infrared thermal imager. The temperature of the material obtained by the infrared thermal imager is even lower, and the thickness is also very thin, which is very suitable for the heat insulation and heat dissipation needs in a narrow space.

3. Heat storage and heat preservation, energy saving and emission reduction

The heat can be efficiently and directionally exported through heat transfer materials. In order to meet the dual-carbon concept, this heat cannot be wasted. This innovation center proposes a concept, that is, to cooperate with phase change materials for heat storage, store the heat generated during the operation of lithium batteries through directional heat conduction, and then convert it into other forms at the right time. It is especially suitable as a supplementary means of thermal management system to make up for the temperature difference and balance the entire battery module.